Are you a distributor or importer?

RELIABILITY, RELIABILITY, RELIABILITY

Garima Global manufactures world class cylinder liners for global OEMs and aftermarket brands. Our plant uses the latest technologies like induction melting, centrifugal casting, precision machining, centerless grinding and plateau honing to produce cylinder liners for highly critical applications. Additionally, Garima Global develops and manufactured liner sleeves in any dimension as per customer requirements.

Just like the motor is the heart of the vehicle, the power cylinder is the heart of the motor. This is the location where the power that drives the vehicle is generated. Garima Global provides reliable pistons, piston rings and connecting rods by partnering with vendors of international repute, in addition to the world-class cylinder liners produced at our own plant in India.

The timing of the engine is controlled by its valve train. The valves, valve seats, valve guides, valve springs, tappets, rocker arms, lifters, push rods, camshafts, timing chains / timing belts and timing gears, along with a host of smaller parts like retainers, valve locks etc. work together to control the timing of combustion within the power cylinder. Reliability and fatigue resistance are of prime importance here, since failure of the smallest component like a valve guide or valve seat can cause catastrophic failure of the engine. Garima Global sources these components from leading vendors of valve train parts in India to ensure peace of mind for our customers.

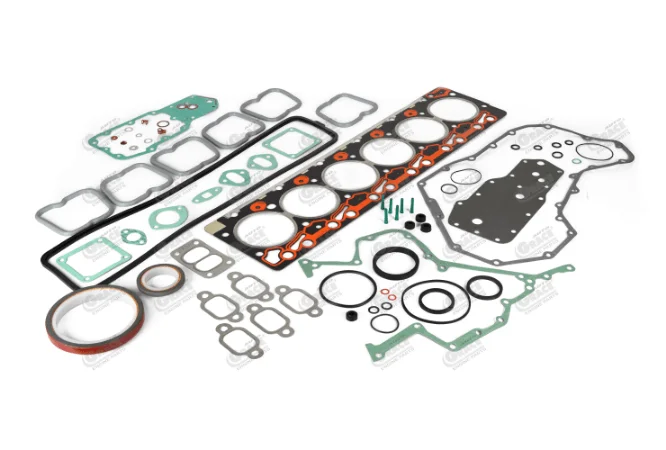

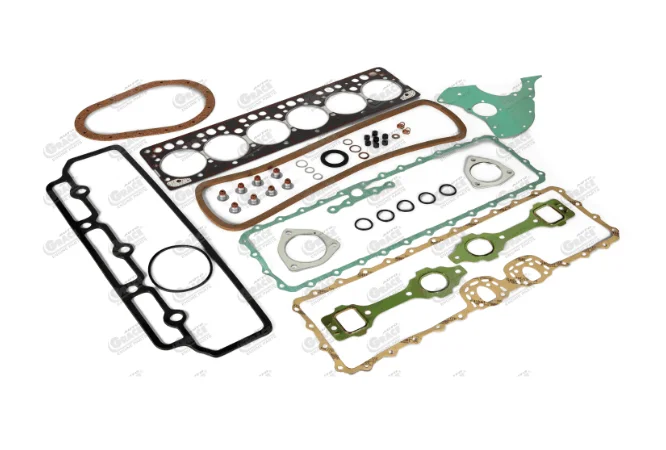

As modern engines continually push the boundaries of temperatures and pressures in search of higher efficiency and more power, sealing systems are becoming increasingly complex. Head gaskets, for example, not only seal the top deck, but also transmit forces between the head and the block. They are, thus, critical in force distribution throughout the engine assembly. These conflicting demands place a heavy burden on the durability of the sealing components which are met by continuous improvement in their design and materials. Crankshaft seal, manifold gasket, oil pan gasket, valve cover gasket and numerous other smaller seals and gaskets form an integral part of the sealing system. AutoGRACE® brand gaskets and seals are produced by leading manufacturers of gaskets and seals in India.

Motors use a host of pumps – oil pumps drive the lubricating system, water / coolant pumps drive the cooling system and fuel pumps inject fuel at high pressures into the power cylinder for combustion. Thus they are critical to the functioning of the engine system. Good quality seals and bearings determine the reliable functioning of these pumps. While pumps are indispensable for engine operation, they also lower the efficiency of the engine because substantial part of the energy generated is utilized in powering the pumps. Choosing the right size and type of pump is critical to reliable and efficient operation of the engine. Hence Garima Global sources engine pumps, repair kits and parts for oil pumps, water pumps and fuel pumps only from the leading manufacturers in India.

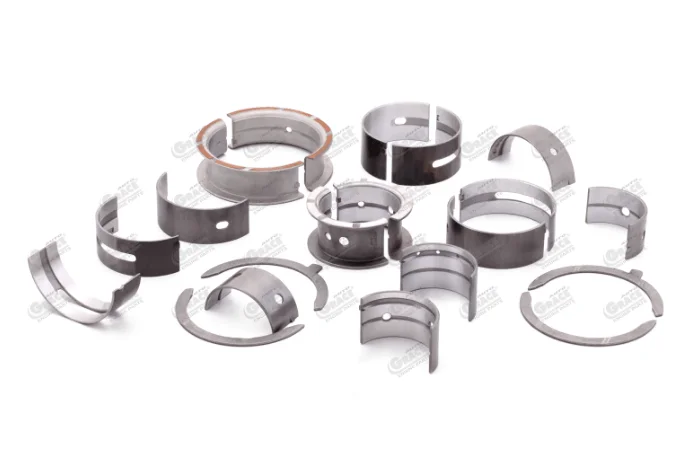

Internal combustion engines employ plain (sliding) bearings instead of rolling bearings due to their ability to withstand shock and ruggedness against grime. They are also more cost effective and can be packaged in to the tight confines of increasingly compact IC engines. The disadvantage is higher friction level. They usually comprise of a steel back coated with the bearing material, usually an alloy of Al-Sn or Cu-Pb-Sn. Since bearings are designed to protect the crankshaft, connecting rod, camshaft and the other shafts they are assembled on, they have a wide variety of failure modes. Hence precise design, correct material choice and consistent manufacturing quality are key to ensure bearings of acceptable quality, which is why Garima Global sources its AutoGRACE® brand big end bearings, main bearings, camshaft bushes, small end bushings and other engine bearings exclusively from the leading OEM and aftermarket factories of engine bearings in India.

Engine Blocks are the biggest component of a typical IC engine, they are the housing in which all the engine components are installed. Satisfying the the myriad, and often conflicting, demands on the engine block places very exacting technical demands on its design and manufacturing. Hence, Garima Global sources engine blocks only from the most technologically advanced and leading manufacturers of engine blocks in India.

The cylinder head assembly has the most impact, of all the engine sub-systems, on the performance of the engine including power, emissions, fuel efficiency, noise and vibration levels etc. Design of the head is influenced by many factors, of which variable valve timing and direct injection are currently the most significant in the development of modern engines.

Considering the staggering complexity in design and manufacturing of cylinder heads, Garima Global has built relationships with leading manufacturers of cylinder heads in India to source high-quality heads for its global customers.

The fuel injection system is undergoing rapid technological changes in modern engines, especially diesel ones. Direct injection, common rails, high-pressure electric fuel pumps are just some of the innovations that have driven design of modern engines. Garima Global procures OEM and AutoGRACE® brand fuel injection system parts from leading manufacturers across the world.

Start the

conversation.

Every beautiful relationship starts with a simple hello. So let’s chat. It might just be the start of something memorable.