Are you a distributor or importer?

Our Flagship product supplied globally to the most demanding customers

Cylinder Liners, also known as engine sleeves, reborer sleeves, wet liners, dry sleeves or simply “liners” are a replaceable wear part which can be changed during engine overhaul service, thus avoiding replacement of the much more expensive engine block. Many modern light duty engines are manufactured by OEMs without any cylinder liners, with the piston running directly inside the block. Such engines may also be rebored during overhaul to a bigger diameter and then a dry liner, or “sleeve” inserted in the rebored block to bring it back to nominal size.

Cylinder Liners are crucial to reduce the total cost of ownership of any engine, by lowering its overhaul time frame and servicing costs. Using a liner is always the better option than using an oversize piston and piston rings on a rebored engine. The additional pressures and loads generated by increasing the volume of the combustion chamber using the latter method results in a shorter overall life of the engine.

In addition to this the cylinder liners serves the following important purposes:

Size Range of Piston in AutoGRACE® Brand

| SPECIFICATION | FROM | TO |

|---|---|---|

| Outer Diameter (mm) | 50.0 | 200.0 |

| Inner Diameter (mm) | 45.0 | 220.0 |

| Length (mm) | 40.0 | 350.0 |

Garima Global supplies components for a wide variety of on-road, off-road, industrial and stationary applications such as: automotive (light duty) and light commercial, trucks (heavy duty), tractors (agricultural), earthmoving and construction machinery, generators, irrigation pumps, and defence / special purpose vehicles.

The brands for which we manufacture and export aftermarket products are Caterpillar, Chevrolet, Chrysler, Citroen, Cummins, Daewoo, DAF, Daihatsu, Detroit Diesel, Deutz, Fiat, Ford, Hino, Honda, Hyundai, International, Isuzu, Iveco, John Deere, Kamaz, Kia, Komatsu, Kubota, Land Rover, Leyland, Lister Petter, Lombardini, Mack, Mahindra, MAN, Massey Ferguson, Mazda, Mercedes Benz, Mitsubishi, Navistar, Nissan, Onan, Perkins, Peugeot, Renault, Scania, Suzuki, Tata, Tatra, Toyota, Ursus, UTB, Volvo, Yanmar and Zetor, amongst others.

Garima Global also export parts for air-brake compressors like Wabco, Bendix, Knorr, Cummins, Clayton Dewandre, Mercedes, Midland etc.

Garima Global has developed an extensive range of components for engine, braking, transmission, suspension, steering, chassis, electrical, lighting and other automotive sub-systems. To assist our customers with choosing the right product for their requirements we have published comprehensive catalogs with engine / vehicle models, interchange with references of OEMs and other popular aftermarket brands, fitment dimensions and other technical data. We strongly encourage you to contact us with your specific requirements so that we can email you the relevant catalogs, and we look forward to starting a mutually beneficial business relationship with you soon!

Classified broadly into monolithic, inserted and bonded designs, the insert technology liners are by far the dominant design due to their ease of repair and lower costs to recondition the block. Within the insert technology cylinders, the main types are:

GGPL manufactures cylinder liners in a wide variety of metallurgical compositions, depending on customer requirements, engine applications and other technical factors. Our customers can specify their proprietary compositions which GGPL is equipped to maintain consistently. GG25 is the standard grade used for most light and medium duty, as well as some heavy duty applications due to its economical cost, excellent wear resistance and oil retention properties. Below are examples of some of the material grades we manufacture.

CHEMICAL COMPOSITION

| ELEMENTS | GG25 | GG25Cr | Cu-Mo Based | Bo Based |

|---|---|---|---|---|

| Carbon (%) | 3.00-3.40 | 3.20-3.50 | 3.15-3.30 | 3.00-3.70 |

| Silicon(%) | 1.80-2.50 | 1.80-2.20 | 1.95-2.15 | 1.50-2.50 |

| Manganese(%) | 0.60-0.80 | 0.60-0.80 | 0.50-0.65 | 0.50-1.00 |

| Sulphur(%) | 0.00-0.12 | 0.00-0.12 | 0.03-0.10 | 0.00-0.12 |

| Phosphorus(%) | Min 0.35 | 0.65-0.90 | 0.00-0.10 | 0.10-0.50 |

| Chromium(%) | - | 0.00-0.20 | 0.15-0.25 | 0.20-0.40 |

| Copper(%) | - | - | 0.50-0.60 | 0.00-0.25 |

| Nickel(%) | - | - | - | - |

| Molybdenum (%) | - | - | 0.17-0.25 | 0.00-0.25 |

| Boron(%) | - | - | - | 0.05-0.06 |

Other grey cast iron grades like GG20, GG30 etc. are also available.

For enhanced strength and other material properties, AutoGRACE® liners are available in compositions using Chromium, Nickel, Copper, Boron, Molybdenum etc. as per customer requirements.

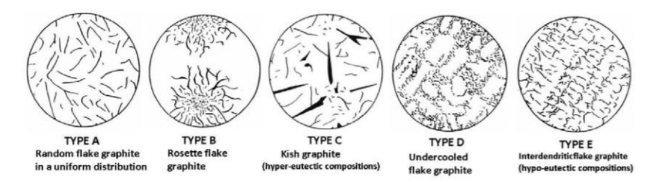

Carbon added to the molten metal forms flakes of graphite in the metal matrix during cooling down of the liner castings. The shape and size of these flakes can be changed by controlling the solidification process.

“Type A graphite flake (random orientation) is preferred because of its superiority in certain wear applications such as the cylinder liners.

Type B graphite flake (rosette pattern) is typical of fairly rapid cooling, such as moderately thin sections (about 10 m, or 38 in.) and along the surfaces of thicker sections, and sometimes results from poor inoculation.

The large flakes of type C graphite are typical of kish graphite that is formed in hypereutectic irons. These large flakes enhance resistance to thermal shock by increasing thermal conductivity and decreasing elastic modulus. On the other hand, large flakes are not conducive to good surface finishes on machined parts or to high strength or good impact resistance.”

Source: Nunes, Rafael, and Telmo Berta. ASM Metals Hand Book Volume 1 Properties and Selection Irons Steels and High Performance Alloys. The Materials Information Company

AutoGRACE® brand cylinder liners exhibit excellent microstructure properties as shown below. We have perfected foundry techniques to generate the right flake type and size. Specimen from each heat is tested for metallurgical composition, hardness and microstructure.

| MICROSTRUCTURE | |

|---|---|

| A + B Type Graphite Flakes | Min 95% |

| Flake Size | 4-6 microns |

| Free Ferrite | Max 5% |

| Matrix | Pearlite |

In addition to metallurgical composition and microstructure, AutoGRACE® liners also confirm to below mechanical properties. Higher grades of cast iron can be requested by our customers as per their requirements.

| MECHANICAL PROPERTIES | |

|---|---|

| Hardness (BHN) | 180-240 |

| Tensile Strength (MPa) | Min 250 |

MATERIAL DESIGNATION a

| Name | Symbol | SI-unit | ISO 185/JL/ 150 |

ISO 185/JL/ 200 |

ISO 185/JL/ 225 |

ISO 185/JL/ 250 |

ISO 185/JL/ 275 |

ISO 185/JL/ 300 |

ISO 185/JL/ 350 |

||||||||||

| Basic Structure | |||||||||||||||||||

| ferritic/ pearlitic |

pearlitic | ||||||||||||||||||

| Tensile strength | Rm | N/mm2 | 150 to 250 | 200 to 300 | 225 to 325 | 250 to 350 | 275 to 375 | 300 to 400 | 350 to 450 | ||||||||||

| 0,1% proof strength | Rp0.1 | N/mm2 | 98 to 165 | 130 to 195 | 150 to 210 | 165 to 228 | 180 to 245 | 195 to 260 | 228 to 285 | ||||||||||

| Elongation | A | % | 0,3 to 0,8 | 0,3 to 0,8 | 0,3 to 0,8 | 0,3 to 0,8 | 0,3 to 0,8 | 0,3 to 0,8 | 0,3 to 0,8 | ||||||||||

| Compression strength | σdb | N/mm2 | 600 | 720 | 780 | 840 | 900 | 960 | 1080 | ||||||||||

No two markets are the same, hence AutoGRACE® liners have been developed in

sizes that match your market. We guarantee the fit and function of our Dry

Sleeves – because we have invested years of effort and experience in developing

the sizes that are appropriate for your reconditioning market

Induction Melting and Centrifugal Casting represent the mature of current foundry technology to manufacture cylinder liners with uniform chemical composition, hardness, microstructure and other material properties throughout the length and wall thickness of the liner.

Cincinnati® centreless grinding machines and plateau honing machines are used to control the geometry and surface finish of outer and inner surfaces of the liners within a very exacting range

Manufactured using the latest and best in foundry and machine shop technology, AutoGRACE® Cylinder Liners are Reliable, Durable and Better than the Competition.

Using CNC based SPMs and machines of highly reputed brands for final finishing operations,

AutoGRACE® Liners are machined to perfection – giving impeccable fit and function.

Start the

conversation.

Every beautiful relationship starts with a simple hello. So let’s chat. It might just be the start of something memorable.