Like a hole in your tooth that makes you go to the dentist, cylinder-liner cavitation can make your diesel car need to go to the shop. Most petrol engine engines have cylinder liners made of cast iron that are pressed into the engine block and can be changed. This doesn’t impact turbodiesel pickups but affects heavy-duty over-the-road vehicles and diesel. The piston moves up and down inside the liner, surrounded by a coolant jacket to keep the engine cool.

When the engine runs, the pistons move up and down in their liners about 3,000 times per minute. At the same time, when the crankshaft turns, it pushes on the piston through the connecting rods.

Contents

How Cylinder-Liner Cavitation Occurs

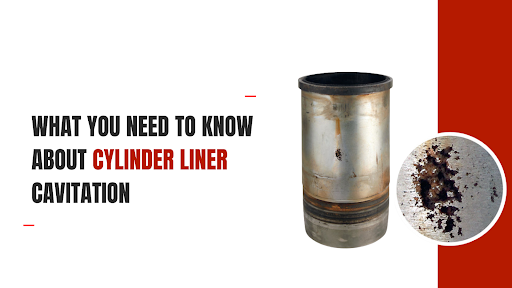

Cylinder-liner cavitation happens when high-pressure coolant is pushed toward the cylinder liner by imploding bubbles. This creates holes through which coolant can enter and mix with oil, which is bad for the engine.

The Role of Engine Coolant

This is the job of the engine coolant, and there are two ways that coolants are usually made to stop cavitation.

Solving the Problem the Old-Fashioned Way

For years, metal salts like nitrites and molybdates have been added to coolants. These salts stick to the liner and form a sacrificial layer that protects the liner. When the coolant bubbles pop, the pressure is taken up by the metallic salts, which break off the surface of the liner instead of the metal itself.

How to Fight Cylinder-Liner Cavitation in A Simple Way

In the worst cases, diesel cylinder-liner cavitation can let oil and coolant mix. Then it’s only a matter of time before the engine breaks down. Here are some things you can do to stop that from happening.

Most diesel engines have cylinder liners made of cast iron that are pressed into the engine block and can be changed. This doesn’t affect turbodiesel pickup trucks, but it does affect heavy-duty over-the-road diesel trucks. The piston moves up and down inside the liner, surrounded by a coolant jacket to keep the engine cool.

How Cylinder-Liner Cavitation Occurs

When the engine runs, the pistons move up and down in their liners about 3,000 times per minute. At the same time, when the crankshaft turns, it pushes on the piston through the connecting rods. Because of these opposite movements, the pistons hit the liners, which causes a lot of shaking, like when you ring a bell.

A high-pressure coolant stream is sent toward the liner when the bubbles pop. The coolant can erode the liner until holes form, like a fast-moving river cutting away at a canyon wall. These holes can get bigger and break through the liner if nothing is done, letting oil and coolant mix. Once that happens, the engine will break down soon after.

The Old-Fashioned Way

For years, metal salts like nitrites and molybdates have been added to coolants. These salts stick to the liner and form a sacrificial layer that protects the liner. When the coolant bubbles pop, the pressure is taken up by the metallic salts, which break off the surface of the cylinder liner instead of the metal itself. Metallic salts naturally break down over time, so drivers must add a supplemental coolant additive (SCA) to the coolant reservoir every so often. This is usually done halfway through the service interval.