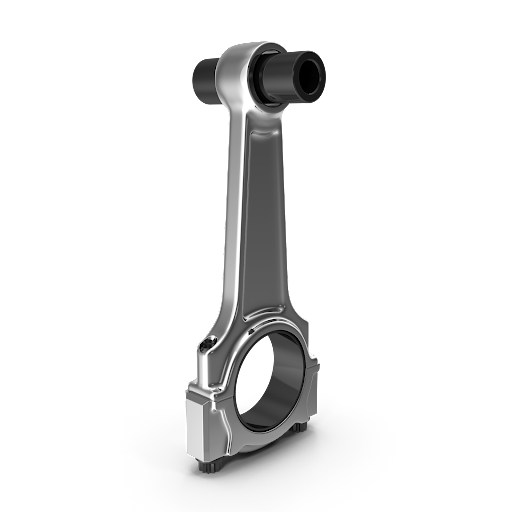

The engine’s fundamental component is the connecting rod. It turns the crank shaft, which aids in spinning the wheels of any vehicle’s engine. Between the engine’s crank and piston, it is located. It is made to withstand pressures brought on by combustion and piston movement. The component is lightweight. A connection rod’s primary function is to allow fluid motion between pistons and a crankshaft. Therefore the load the piston represents puts a lot of pressure on the connecting rod. The connecting rod is given much consideration when constructing a high-performance engine. A connecting rod’s consistent shape should be its most helpful characteristic. Below mentioned points are connection rod design and analysis for weight and stress reduction:

Contents

Connecting Rod In The Engine

The primary purpose of a connecting rod is to change rotating motion from reciprocating motion and vice versa. It was dragging and pushing a piston that could transfer energy. This causes the rod and cranks to turn. It is often referred to as the engine’s heart. Mainly for an engine’s working mechanism, it performs piston pushing and pulling activities. For a machine to start and move the machinery it is utilized in, this generates power. It is most frequently used in car engines. Any vehicle with a combustion engine, including cars, trucks, and bikes, uses a connecting rod. This connecting rod-using engine will be found in all commercial vehicles.

Working Of A Connecting Rod

Finite Element techniques simplify analyzing the structural systems of connecting rods. Thus, a suitable Finite Element Model is created using CAD software. Using finite element analysis software, static analysis is then performed to calculate the von Misses stress, shear stress, elastic strain, and total deformation in the connecting rod of the current design under the specified loading circumstances.

Performance Of The Engine

The material of the connecting rod and the connecting rod’s weight are the two parameters that impact an engine’s performance. The machine’s efficiency is determined by how much force is expended to move the connecting rod during the power stroke. Less efficiency results from using more energy to move the connecting rod.

Design Of A Connecting Rod

A connecting rod is a piece of machinery that experiences alternate direct compressive and tensile forces. The compressive forces are significantly more significant than the tensile forces, the connecting rod’s cross-section is built as a strut, and the Rankine formula is applied. A connecting rod subjected to an axial load may budge along the x and y axes. The connecting rod is seen as having both hinged ends for buckling about the x-axis and both fixed ends for buckling about the y-axis. A connecting rod should be capable of buckling equally well around either axis.

Final Words

It was discovered that the Connecting Rod is built for the engine’s maximum speed and gas pressure. According to the finite element analysis results, there is a significant amount of material removal from the connecting rod’s big, small, and area linking the two ends. Its thickness can be reduced based on the conclusions drawn from the analytical calculations. It was noted that the previous connecting rod is heavier than the new connecting rod geometry.